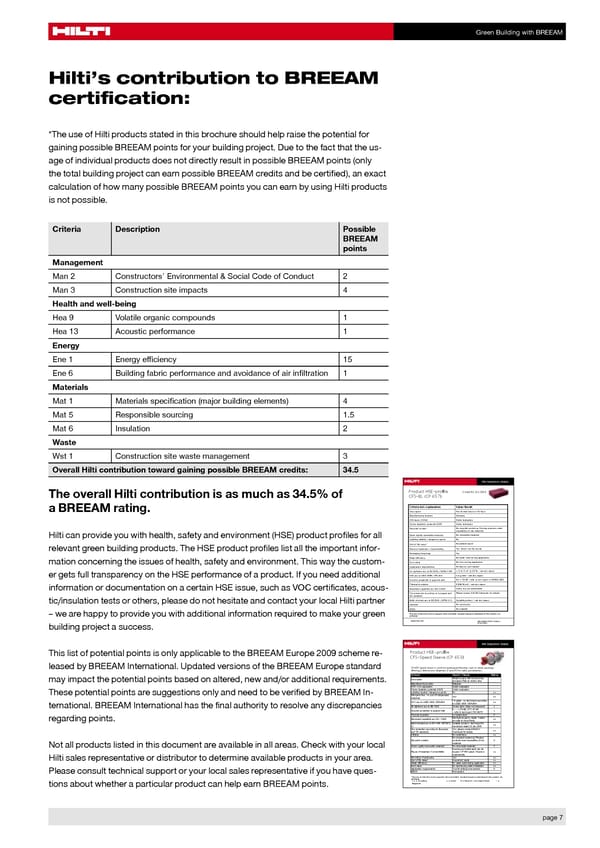

Green Building with BREEAM Hilti’s contribution to BREEAM certification: *The use of Hilti products stated in this brochure should help raise the potential for gaining possible BREEAM points for your building project. Due to the fact that the us- age of individual products does not directly result in possible BREEAM points (only the total building project can earn possible BREEAM credits and be certified), an exact calculation of how many possible BREEAM points you can earn by using Hilti products is not possible. Criteria Description Possible BREEAM points Management Man 2 Constructors' Environmental & Social Code of Conduct 2 Man 3 Construction site impacts 4 Health and well-being Hea 9 Volatile organic compounds 1 Hea 13 Acoustic performance 1 Energy Ene 1 Energy efficiency 15 Ene 6 Building fabric performance and avoidance of air infiltration 1 Materials Mat 1 Materials specification (major building elements) 4 Mat 5 Responsible sourcing 1.5 Mat 6 Insulation 2 Waste Wst 1 Construction site waste management 3 Overall Hilti contribution toward gaining possible BREEAM credits: 34.5 Product HSE-profile Issued 01.Oct.2010 The overall Hilti contribution is as much as 34.5% of CFS-BL (CP 657) Criteria incl. explanation Value/Result a BREEAM rating. Description Pre-formed block on PU basis Manufacturing location Germany CO 2 equiv. (CO2e) Under evaluation Ozone depletion potential (ODP) Under evaluation No recycled content as Firestop products need Recycled content traceability of raw materials No renewable materials Hilti can provide you with health, safety and environment (HSE) product profiles for all Share rapidly renewable materials: Labeling needed / dangerous goods No Household waste End of life status¹ Yes, blocks can be reused relevant green building products. The HSE product profiles list all the important infor- Reuse of materials / Convertibility Yes Packaging (recycling) No water used during application Water e昀케ciency No dust during application mation concerning the issues of health, safety and environment. This way the custom- Dust value No electric tool needed Application requirements < 6 m³/h m² at 50 Pa – see test report Air tightness acc to EN 1026 / ASTM E 283 er gets full transparency on the HSE performance of a product. If you need additional VOC acc to LEED 2009 / EPA #24 4,4 g/liter – see test report Rw = 50 dB – refer to test report A 48389/3093 Acoustic properties in gypsum wall 0,066 W/mK – see test report Thermal insulation Given, but not determined information or documentation on a certain HSE issue, such as VOC certificates, acous- Movement capability acc ISO 11600 Please contact Hilti BU Chemicals for details Fire protection according to European and US standards tic/insulation tests or others, please do not hesitate and contact your local Hilti partner Mold resistant acc to ISO 846 / ASTM G 21 Suitable product – see test report No restrictions Lifetime MSDS Not needed ¹Provision of statement concerning waste status (recyclable, standard disposal or hazardous) of Hilti products incl. – we are happy to provide you with additional information required to make your green packaging www.hilti.com HSE-Profile CP 657 I CEPsp I building project a success. 01.10.2010 This list of potential points is only applicable to the BREEAM Europe 2009 scheme re- Product HSE-profile CFS-Speed Sleeve (CP 653) leased by BREEAM International. Updated versions of the BREEAM Europe standard CP 653 Speed Sleeve is used for permanent firestop seals in small openings o昀昀ering 2 dimensions (diameter 2”and 4”) for cable penetrations. Criteria Result / Values Rating Description Metal housing with firestop inlay may impact the potential points based on altered, new and/or additional requirements. and glass fiber as smoke stop Manufacturing location Malaysia PCF: CO2 equivalent Under evaluation Ozone depletion potential (ODP) Under evaluation These potential points are suggestions only and need to be verified by BREEAM In- Labeling needed / dangerous goods No ++ Halogene free - no use of halogenated Yes ++ materials VOC acc to LEED 2009 / EPA #24 7,6 g/liter - no test report according ++ to LEED 2009 / EPA #24 ternational. BREEAM International has the final authority to resolve any discrepancies Air tightness acc to EN 1026 Smoke tight. Value not measured. + Acoustic properties in gypsum wall Dn,e,w = 54 dB, STC 47 dB + – refer to test report 164 44278 Thermal insulation not determined 0 Movement capability acc ISO 11600 Mechanical part is stable. Cables ++ regarding points. are able to move freely Mold resistant acc to ISO 846 / ASTM G Suitable product – test report for ++ 21 membrane dated 23.Jan 2008 Fire protection according to European Yes, please contact Hilti BU ++ and US standards Chemicals for details Lifetime No restrictions ++ No recycled content as Firestop Recycled content products need traceability of raw 0 materials Not all products listed in this document are available in all areas. Check with your local Share rapidly renewable materials: No renewable materials 0 Housing and matal parts can be Reuse of materials / Convertibility reused. CP 653 speed Sleeve is ++ repenetrable Hilti sales representative or distributor to determine available products in your area. Recycling of packaging Yes ++ End of life status¹ Household waste ++ Water efficiency No water used during application ++ Dust value No dust during cable installation ++ Application requirements Tool for drilling hole needed 0 MSDS Not needed Please consult technical support or your local sales representative if you have ques- ¹ Provision of statement concerning waste status (recyclable, standard disposal or hazardous) of Hilti products incl. packaging ++ = Excellent + = Good 0 = Neutral / not determined - = tions about whether a particular product can help earn BREEAM points. Negative Issued Feb 2011 BU Chemicals, Product Care www.hilti.com HSE-Profile I CEPsp page 7

Green Building with BREEAM Page 6 Page 8

Green Building with BREEAM Page 6 Page 8